WATERJET CUTTING

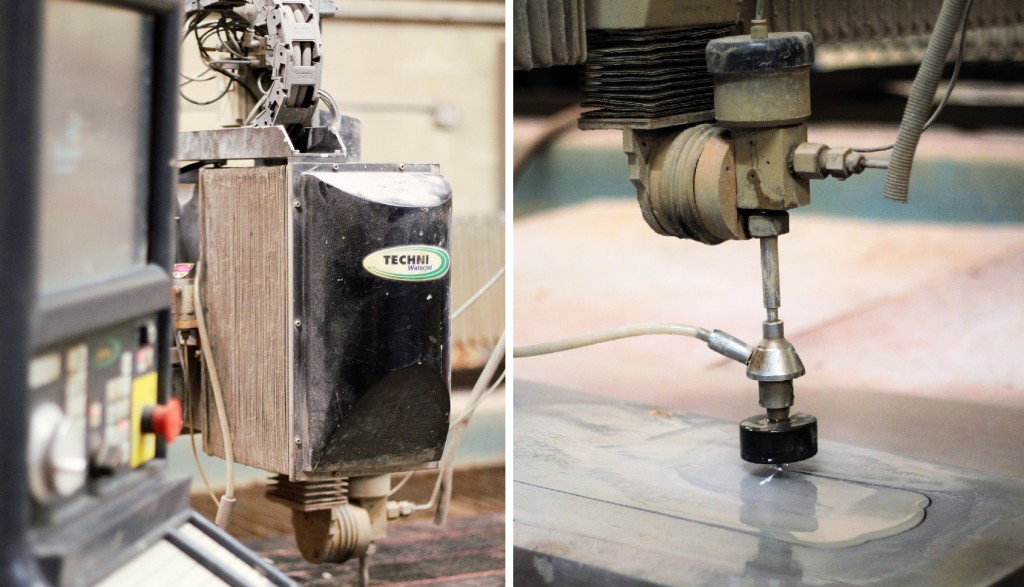

Waterjet cutting uses very high pressure (50,000 psi) water in a very fine stream (from .008” to .043”) to wear away material to make a cut. There is no heating of the material, there are minimal machining marks, and everything is computer controlled, allowing changes to be made with minimal effort. An intensifier creates high pressure by use of a piston pump. A diamond or ruby with a very small hole is located at the head of the machine. The head moves in X-Y axes and cuts the material. All of this is controlled by a CNC controller which uses special software to manipulate the head as needed.

Exact Cut uses both water-only and abrasive waterjet cutting. Water-only means we can use a smaller stream to cut softer material quickly and with less mess. This is often used for foam, rubber, thin plastics, etc. Abrasive water jet cutting mixes an abrasive (garnet rock, graded by size– see picture) in with the stream and through a focusing tube. This allows us to cut very hard and thick materials, such as steel, aluminum, stainless steel, copper, bronze, thick plastic, stone, glass, etc.

Special software determines the speed, piercing, and edge quality of the cut based on the material and machine set up. Also compensation for the width of the stream is calculated to create a very accurate cut.

Our capabilities include being able to cut sheets that are 144” long by 72” wide by 6” thick. Tolerance of the cut can be as tight as +/- .010” depending on material and thickness (softer and thicker materials are less accurate). There are not many materials that cannot be cut with our waterjet.

Waterjets offer many advantages over other fabricating processes,  including:

including:

- No heat to affect material

- Can cut materials up to 6″ thick

- Cutting is computer controlled for quick delivery and low set-up cost

- Computer control allows efficient nesting of parts in material

- Minimal machining marks

- Changes can be made with minimal effort

- Wide variety of materials can be cut

- Environmentally friendly

- Large cutting size – 6′ x 12′