3D PRINTING

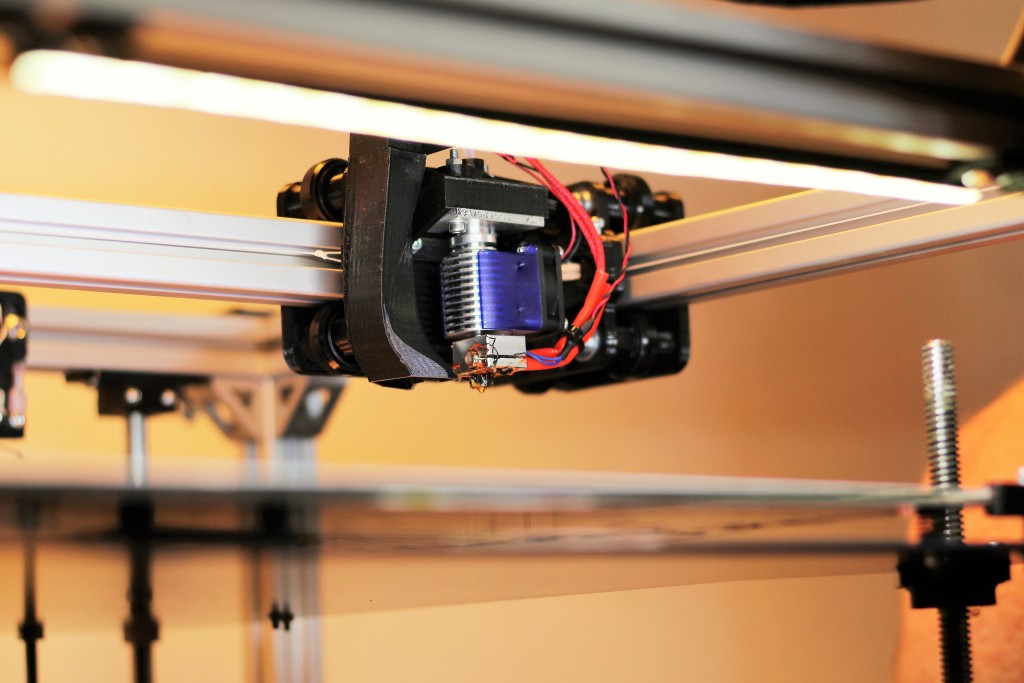

3D printing is one of the newest forms of manufacturing. We use a plastic extrusion 3D printer. This process extrudes melted plastic onto a bed in a 2 axes pattern and then lowers the bed for the next pattern to be laid down. This allows complete parts to be “printed”. A better term is additive manufacturing.

The process starts with a software 3D model of the

part desired. This model is then “sliced” with a program into layered 2D patterns that are printed in order.

The software then instructs a heated extrusion head to move in 2 dimensions and advances a plastic filament to be melted in the head and be laid in place. Then the software lowers the bed one level and repeats the process. If the software detects that a print will be over a void, a “support raft” is created on lower levels that can be printed upon and broken off after the part is complete. If you can draw a model, we can create a part.

We can print ABS or PLA material. There are different colors available, but we use black most often. Our printing envelope is 12” x 12” x 12”.